A 1300hp Custom R35 GTR That’s BuiltFor Form And Function

Photos by: Ricky Rigutto | Words by: Ian Lee

The GTR has long been one of those iconic 90’s JDM car badges that along with the Supra have earned their stripes over the years as being thoroughbred and genuine “supercar killers”. A quick YouTube search for “GTR vs. Lambo” will return plenty of videos of supercar owners being surprised and often humbled by the performance of a car often more than half the price of theirs. So naturally, when the reintroduction of the GTR debuted in 2008, expectations were rather high for what the crazy engineers in Nissan had cooked up for the world. Boasting a blistering 3.2 second 0-100 speed and a 12 second quarter mile, the new GTR definitely commanded respect from the automotive community and for Tony this debut started his 7 year wait to finally be in the position to buy his own one brand new in 2015.

It took just three months for Tony to succumb to the urge of modifying his new GTR. Now what could possible drive someone with a car possessing these kind of figures and performance to want such a quick change? Easy, you take it racing. Tony says he had no idea how much of a competitive person he was until he took the car to a Downshift happy laps event in Queensland. Despite besting most of the races that day, a single and only loss was enough to drive Tony to the edge and vow to come back and never lose another race again.

By this time, the GTR had been in the market for about 6 years and the aftermarket scene was pretty established for this VR38 platform. So with some quick online purchases for basic bolt ons and a retune on e85, the car was back on the road with 450kw at the wheels. After a few more casual race events, Tony got introduced to the now annual Bullrush Rally and knew he didn’t want to rock up in a stock looking GTR. Some 3 piece forged wheels from Strauss, lowering springs and aftermarket exhaust with gold tips were ordered and the car pretty much stayed like this for two years. However, a semi-final elimination at Queensland Raceway during a roll racing event paired with Tony’s competitive nature would mark the beginning of a very long, painful and expensive journey to the car you see today.

With roll racing fast becoming a pretty popular past time for owners wanting to push their car’s limits, big power is a must and Tony knew his simple bolt ons were not going to be sufficient. With near 1000hp figures in mind as a target, Tony commissioned his workshop to assemble this package to the eye watering tune of nearly $35,000. A fully built HKS motor with new internals, crank, high HP rated intercooler and GT9000 turbos topped the bill. Other costs were allocated to transmission and supporting mods which included an Albins gear set, Dodson clutch kit, 2000cc injectors and parts from AMS performance whom have built quite the rep in the States for all things GTR over the years.

A 102mm FI valvetronic exhaust, Endless 6 piston calliper brake kit and upgraded carbon steel rotors capped off all the to do list as far as the mechanical side went. Not wanting to have to take the car off the road later to modify the exterior, Tony decided to freshen up the now dated MY15 looks by getting a full MY17 v3 body kit from Top Secret. The six month wait and price tag are probably the reason Tony’s car is still the only one in Australia to rock this particularly aero kit. Lastly, a set of hydraulic lift enabled KW coilovers were added to get the most from the body kit and wheel combo that the car has. The finished look really does improve the overall aggressiveness of the car particularly with the exposed carbon body panels, gold accented pieces and subtle paint work.

With a proposed three month build time for the engine, Tony was dying to get the car back to experience what a 1000hp GTR would feel like. Three months came around and unfortunately the car was not ready so disappointingly Tony waited for the build to play catch up. Another three months came and went and after that, yet another three months came by – something was clearly wrong. Alarm bells were going off in Tony’s mind and by the time he finally got the car from the workshop, things felt even more off.

After another twelve months of going back and forth with the workshop trying to diagnose the cars problems, Tony cut his losses and took to enlisting the services of Aaron from Precision Racing. Initial discussions and remote diagnosis indicated that many of the problems possibly stemmed from the Cobb Accessport ECU being used, not a big deal but frustrating none the less. Aaron and Tony agreed to upgrade to a Precision Racing GTR Motec package and with that Tony made the trip down to Sydney to get the installation done. Enter problem number two.

During the drive down the fully built, billet front diff decided to let go and just like that, $7,000 went down the drain. What was meant to start off as a simple ECU install now became an engine out job to replace the diff which by the way was returned to stock anyway. With patience nearing empty, the car after being fixed up with a new diff and ECU was finally ready to be re-tuned to rid the car of its originally problems. Once on the dyno and with boost turned up, problem three reared its ugly head and the car started pushing water and coolant out from the block and at that point, Tony had finally hit rock bottom for his dream build. The root cause as it turned out were the type of engine sleeves used on the block which as a result of removing too much material, actually cause the block to flex slightly and eventually push water when pushed to extreme power.

Not wanting to compromise and settle on a lower power tune to avoid pushing fluid, Tony went on to have many ‘spirited’ phone calls with the previous builder demanding answers and solutions to no avail. It’s often risky business when assembling a car to use multiple parties as if and when things go wrong, it’s often a finger pointing competition and unfortunately this was exactly what panned out for Tony. The original builder denied accountability for the failure and wiped their hands clean of any fault. Just like that, $35,000 was gone on an engine that had just passed run in mileage. Tony says that just recounting this experience gives him a whopper of a headache thinking about the most expensive 2000 km journey he’s taken in his life.

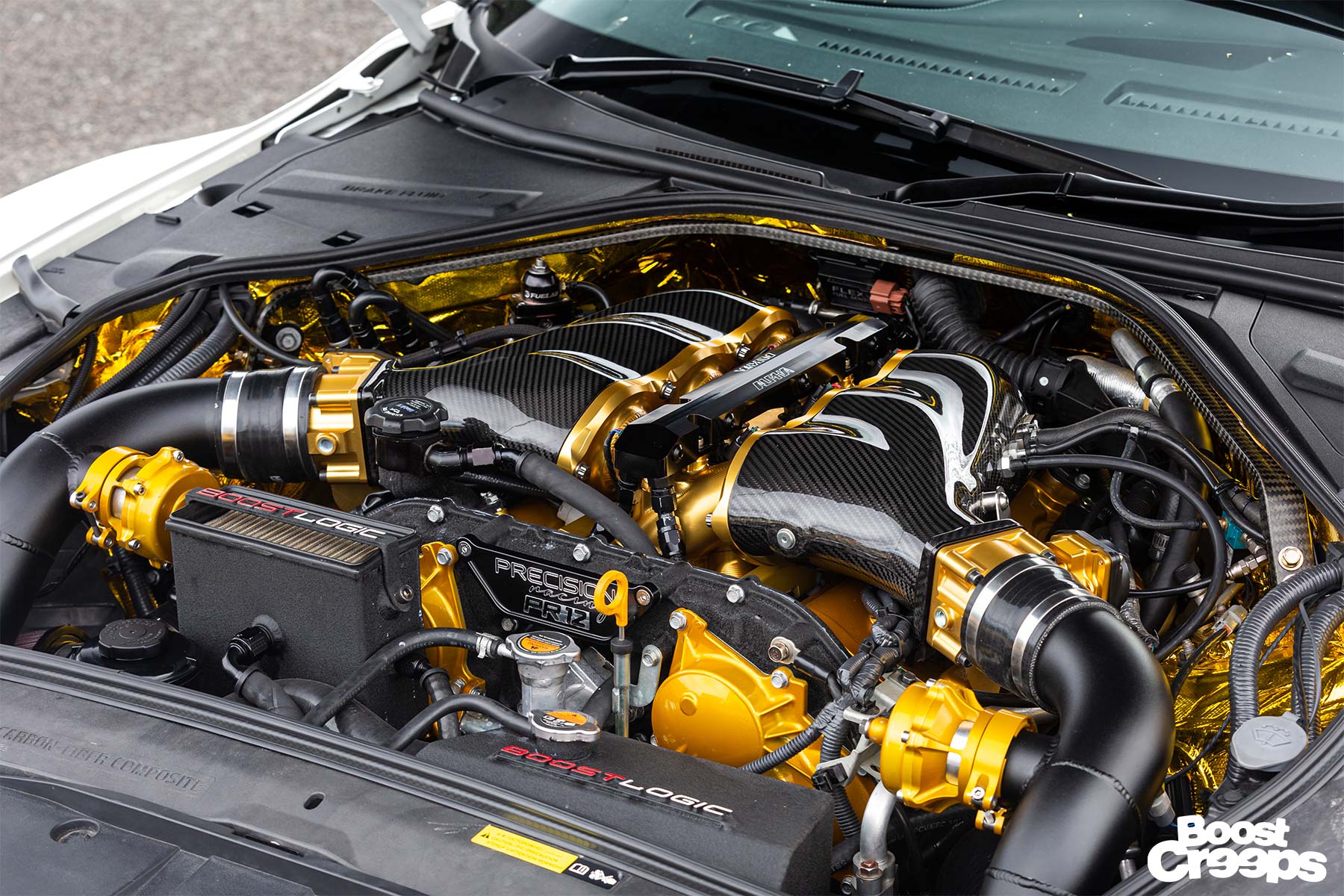

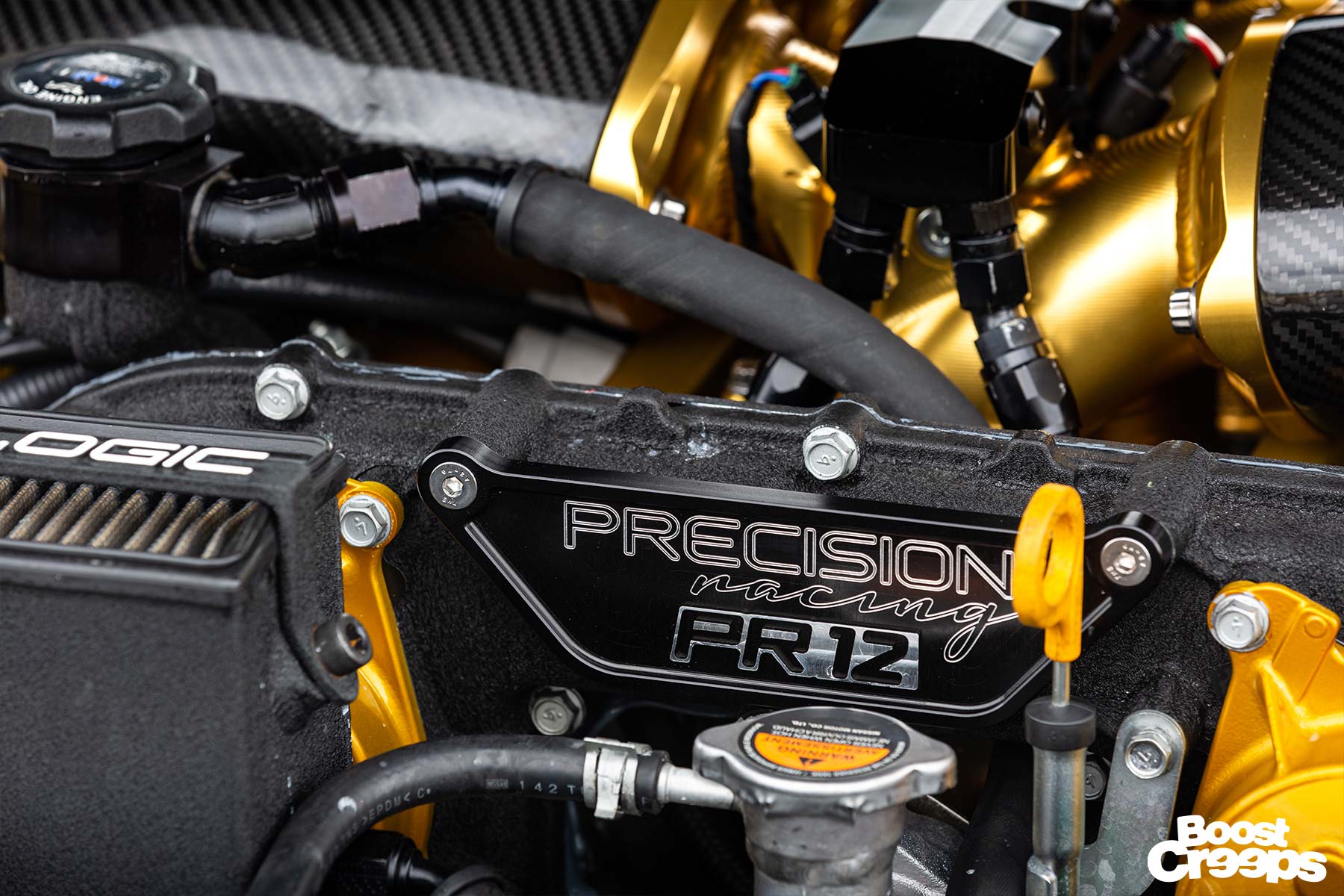

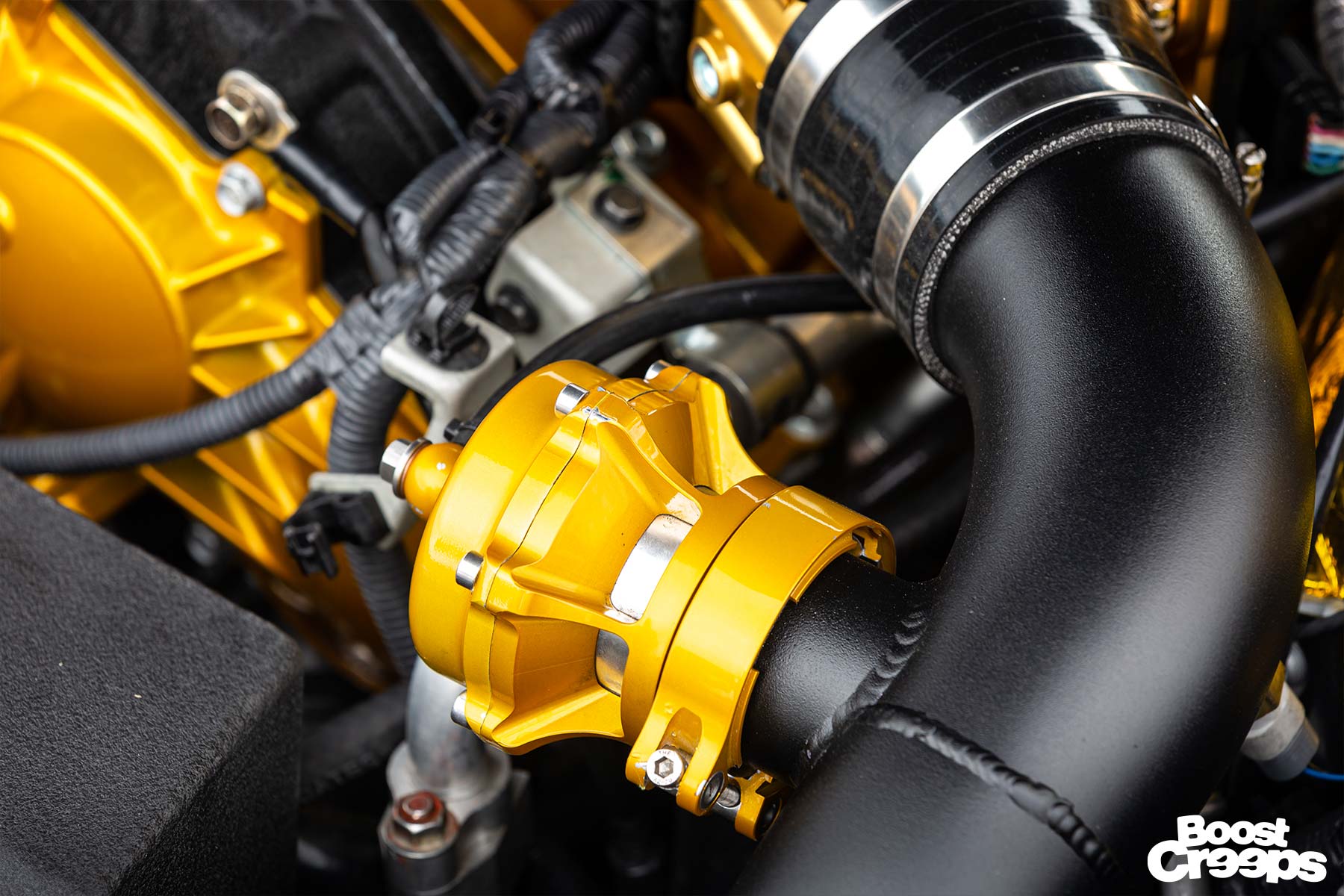

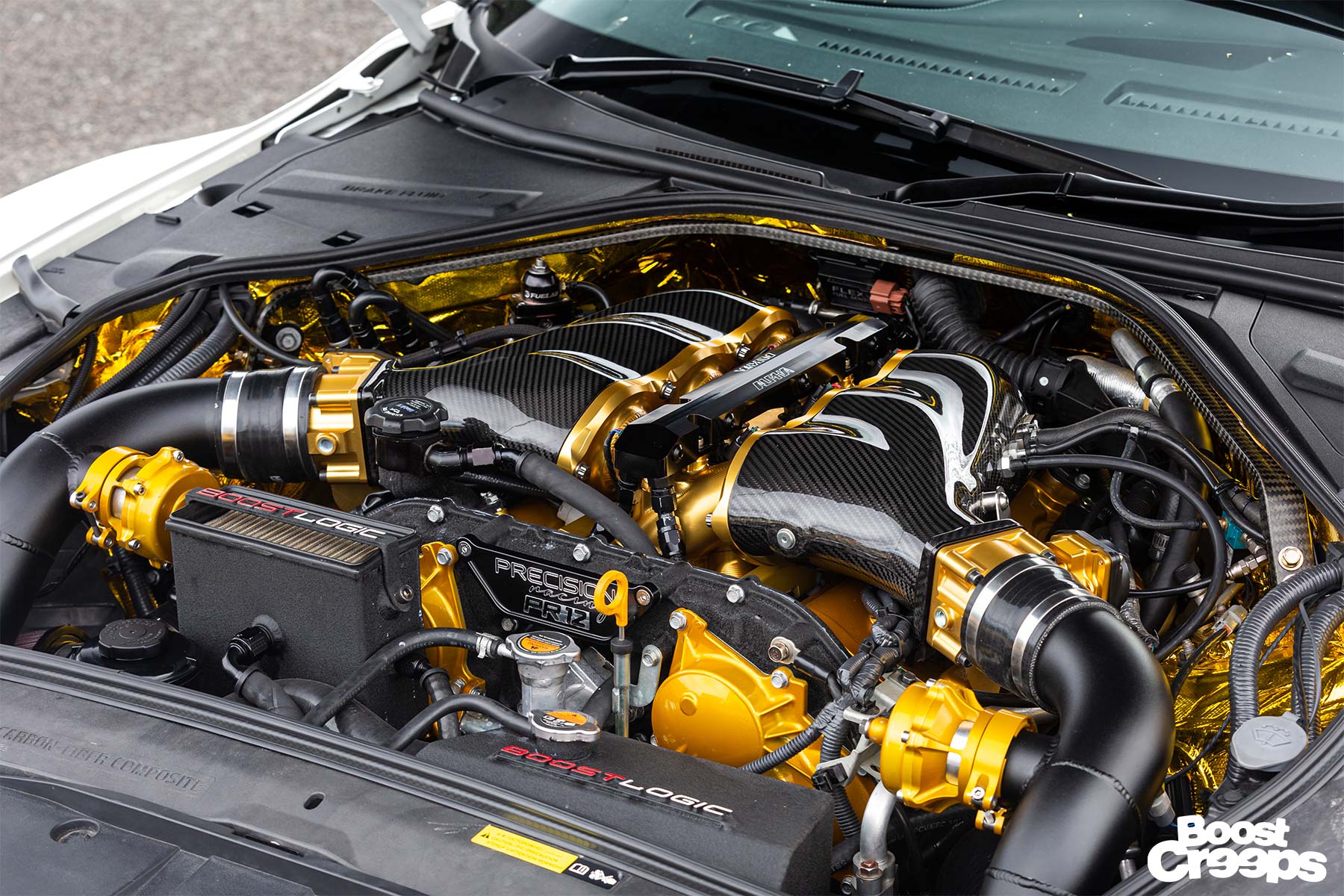

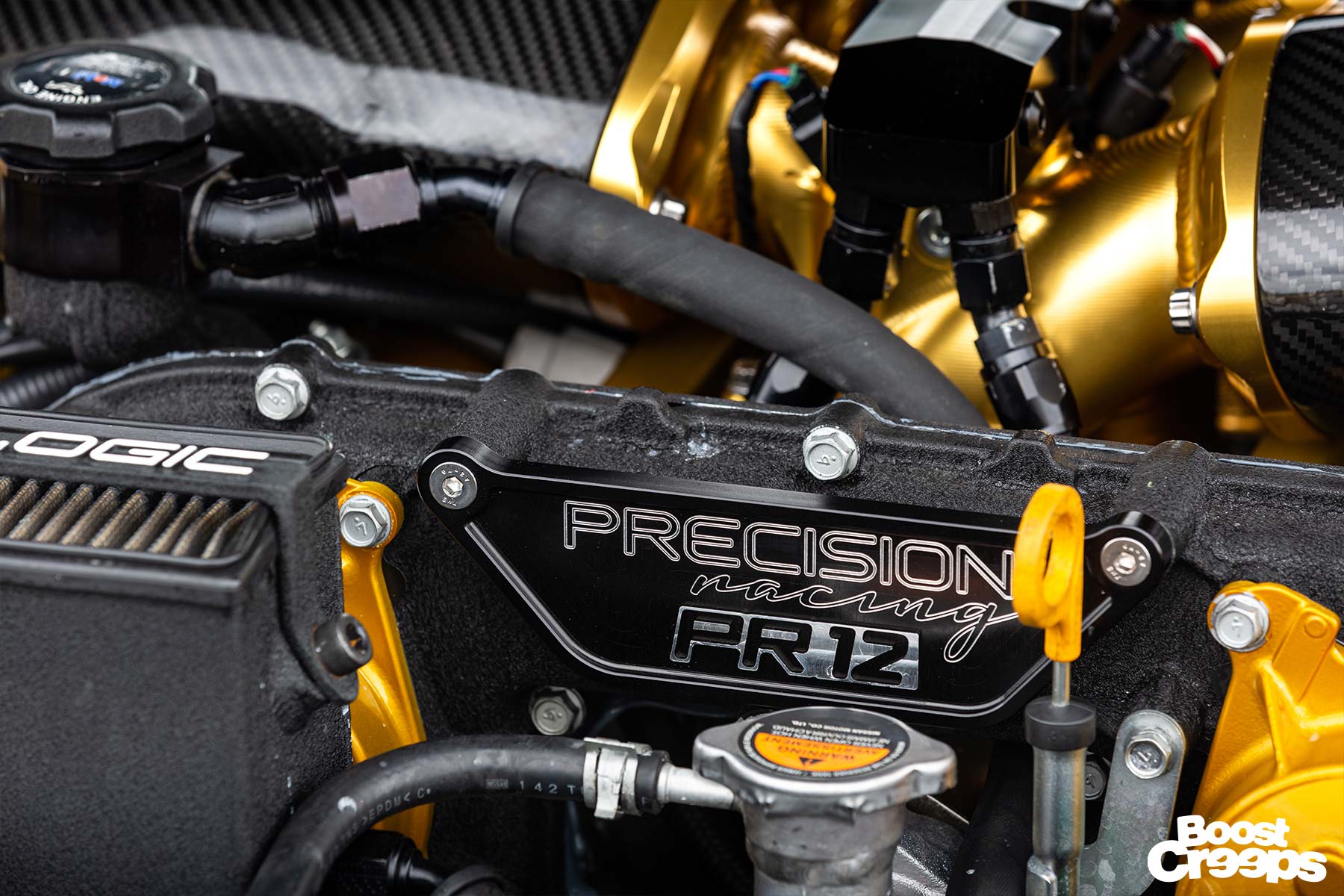

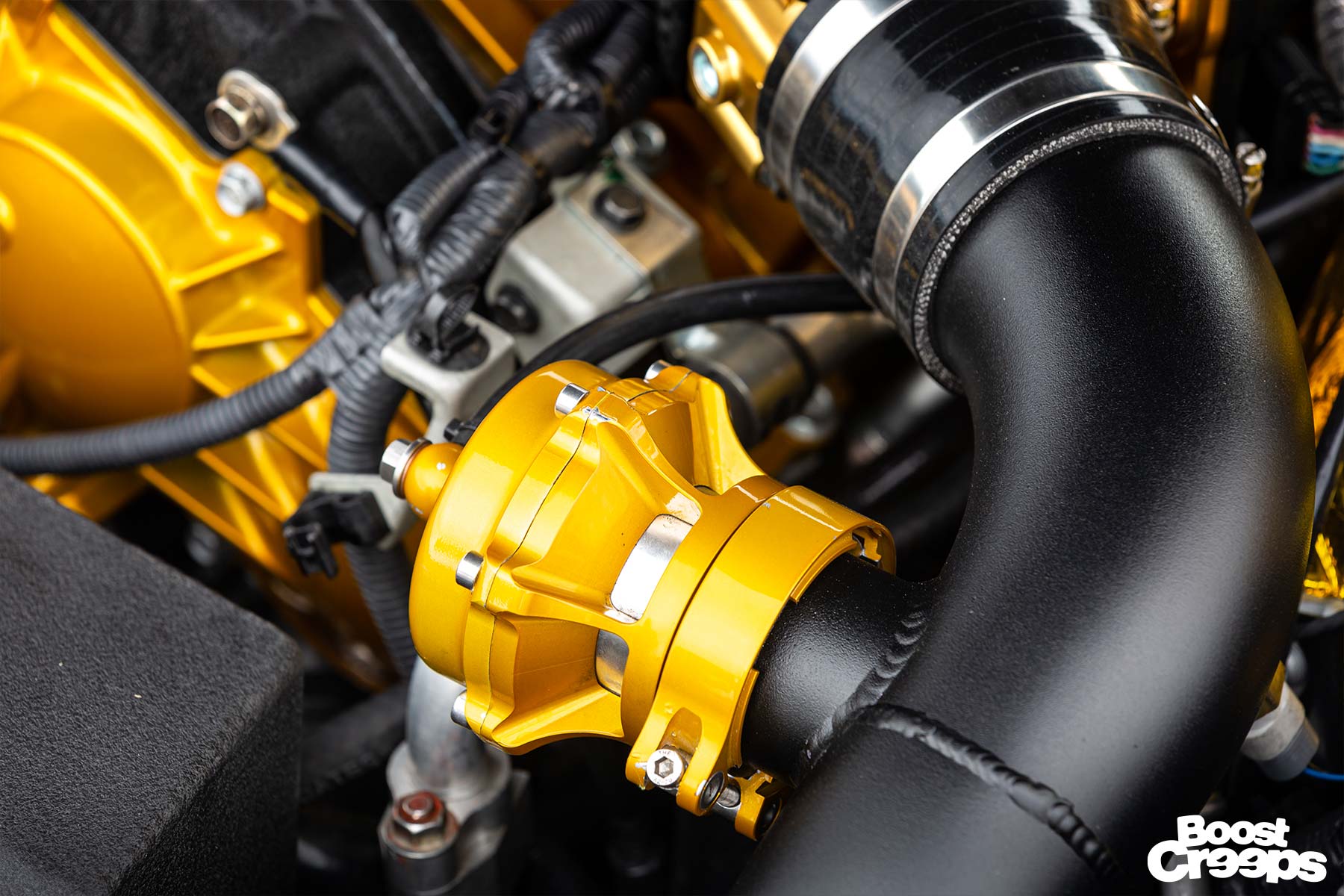

Left to assess his options, Tony figured the sensible routes were to: a) rebuild the head b) turn the power down c) return the car to stock and rid it. However Tony isn’t quite the sensible type and the resulting solution was as far away from options a, b and c put together. Putting his faith into Aaron and his team, the plan was to buy a completely brand new VR38 and rebuild this from scratch with a PR12 Garrett turbo kit. Advertised as a stage 5 GTR package, this kit basically turns the potent GTR performance into a mid to low 8 second car which includes all new conrods, pistons, cylinder heads, modified crank, billet sump and pretty much anything else you can think of. An increased 12 injector setup with 6 of them running ID1700 is hidden beneath the incredible looking carbon fibre AMS manifold that helps break up the gold in the engine bay.

To fix some of the clutch slip Troy was experiencing on the initial build as a result of the high horsepower, PPG drop gears and a 10+10 plate clutch kit with billet pistons and T1 rear diff brace were installed. The end result, a mind boggling 1300hp which Tony says has never failed to get a smile along with plenty of profanity from anyone who’s lucky enough to get a spin in his car. Oh and the cost of this? From Precision’s website you’re looking at $138k excluding the motor. Let’s just say after tallying the costs for the car, the gold theme becomes very appropriate.

When things go wrong with cars during the modification process, its very easy to cuss out, lose motivation and call it quits. This is even more amplified when the car you’re modifying already cost over $100k and you’ve just lost an additional $40k on a blown engine and diff so to that, I think there’s no denying Tony’s perseverance to carry on. Despite the setbacks, sleepless nights during his build failure and thousands of lost dollars, Tony says when he’s ripping it down Queensland Raceway he instantly forgets these past experiences and enjoys the moment he’s in. Tony would like to call out his thanks to Aaron and team from Precision Racing, Lucas from Vouge Industries, Cameron and Joshua Hill for the body work and most importantly his wife who’s been patient and supportive throughout the entire process, no matter how stupid it may have seemed at the time.

A 1300hp Custom R35 GTR That’s Built For Form And Function

The GTR has long been one of those iconic 90’s JDM car badges that along with the Supra have earned their stripes over the years as being thoroughbred and genuine “supercar killers”. A quick YouTube search for “GTR vs. Lambo” will return plenty of videos of supercar owners being surprised and often humbled by the performance of a car often more than half the price of theirs.

So naturally, when the reintroduction of the GTR debuted in 2008, expectations were rather high for what the crazy engineers in Nissan had cooked up for the world. Boasting a blistering 3.2 second 0-100 speed and a 12 second quarter mile, the new GTR definitely commanded respect from the automotive community and for Tony this debut started his 7 year wait to finally be in the position to buy his own one brand new in 2015.

It took just three months for Tony to succumb to the urge of modifying his new GTR. Now what could possible drive someone with a car possessing these kind of figures and performance to want such a quick change? Easy, you take it racing. Tony says he had no idea how much of a competitive person he was until he took the car to a Downshift happy laps event in Queensland. Despite besting most of the races that day, a single and only loss was enough to drive Tony to the edge and vow to come back and never lose another race again. By this time, the GTR had been in the market for about 6 years and the aftermarket scene was pretty established for this VR38 platform. So with some quick online purchases for basic bolt ons and a retune on e85, the car was back on the road with 450kw at the wheels.

After a few more casual race events, Tony got introduced to the now annual Bullrush Rally and knew he didn’t want to rock up in a stock looking GTR. Some 3 piece forged wheels from Strauss, lowering springs and aftermarket exhaust with gold tips were ordered and the car pretty much stayed like this for two years. However, a semi-final elimination at Queensland Raceway during a roll racing event paired with Tony’s competitive nature would mark the beginning of a very long, painful and expensive journey to the car you see today.

With roll racing fast becoming a pretty popular past time for owners wanting to push their car’s limits, big power is a must and Tony knew his simple bolt ons were not going to be sufficient. With near 1000hp figures in mind as a target, Tony commissioned his workshop to assemble this package to the eye watering tune of nearly $35,000. A fully built HKS motor with new internals, crank, high HP rated intercooler and GT9000 turbos topped the bill. Other costs were allocated to transmission and supporting mods which included an Albins gear set, Dodson clutch kit, 2000cc injectors and parts from AMS performance whom have built quite the rep in the States.

A 102mm FI valvetronic exhaust, Endless 6 piston calliper brake kit and upgraded carbon steel rotors capped off all the to do list as far as the mechanical side went. Not wanting to have to take the car off the road later to modify the exterior, Tony decided to freshen up the now dated MY15 looks by getting a full MY17 v3 body kit from Top Secret. The six month wait and price tag are probably the reason Tony’s car is still the only one in Australia to rock this particularly aero kit. Lastly, a set of hydraulic lift enabled KW coilovers were added to get the most from the body kit and wheel combo that the car has. The finished look really does improve the overall aggressiveness of the car particularly with the exposed carbon body panels and gold accented.

With a proposed three month build time for the engine, Tony was dying to get the car back to experience what a 1000hp GTR would feel like. Three months came around and unfortunately the car was not ready so disappointingly Tony waited for the build to play catch up. Another three months came and went and after that, yet another three months came by – something was clearly wrong. Alarm bells were going off in Tony’s mind and by the time he finally got the car from the workshop, things felt off.

After another twelve months of going back and forth with the workshop trying to diagnose the cars problems, Tony cut his losses and took to enlisting the services of Aaron from Precision Racing. Initial discussions and remote diagnosis indicated that many of the problems possibly stemmed from the Cobb Accessport ECU being used, not a big deal but frustrating none the less. Aaron and Tony agreed to upgrade to a Precision Racing GTR Motec package and with that Tony made the trip down to Sydney to get the installation done. Enter problem number two.

During the drive down the fully built, billet front diff decided to let go and just like that, $7,000 went down the drain. What was meant to start off as a simple ECU install now became an engine out job to replace the diff which by the way was returned to stock anyway. With patience nearing empty, the car after being fixed up with a new diff and ECU was finally ready to be re-tuned to rid the car of its originally problems. Once on the dyno and with boost turned up, problem three reared its ugly head and the car started pushing water and coolant out from the block and at that point, Tony had finally hit rock bottom for his dream build. The root cause as it turned out were the type of engine sleeves used on the block which as a result of removing too much material, actually cause the block to flex slightly and eventually push water when pushed.

Not wanting to compromise and settle on a lower power tune to avoid pushing fluid, Tony went on to have many ‘spirited’ phone calls with the previous builder demanding answers and solutions to no avail. It’s often risky business when assembling a car to use multiple parties as if and when things go wrong, it’s often a finger pointing competition and unfortunately this was exactly what panned out for Tony. The original builder denied accountability for the failure and wiped their hands clean of any fault. Just like that, $35,000 was gone on an engine that had just passed run in mileage. Tony says that just recounting this experience gives him a whopper of a headache.

Left to assess his options, Tony figured the sensible routes were to: a) rebuild the head b) turn the power down c) return the car to stock and rid it. However Tony isn’t quite the sensible type and the resulting solution was as far away from options a, b and c put together. Putting his faith into Aaron and his team, the plan was to buy a completely brand new VR38 and rebuild this from scratch with a PR12 Garrett turbo kit. Advertised as a stage 5 GTR package, this kit basically turns the potent GTR performance into a mid to low 8 second car which includes all new conrods, pistons, cylinder heads, modified crank, billet sump and pretty much anything else you can think of.

An increased 12 injector setup with 6 of them running ID1700 is hidden beneath the incredible looking carbon fibre AMS manifold that helps break up the gold in the engine bay. To fix some of the clutch slip Troy was experiencing on the initial build as a result of the high horsepower, PPG drop gears and a 10+10 plate clutch kit with billet pistons and T1 rear diff brace were installed. The end result, a mind boggling 1300hp which Tony says has never failed to get a smile along with plenty of profanity from anyone who’s lucky enough to get a spin in his car. Oh and the cost of this? From Precision’s website you’re looking at $138k excluding the motor. Let’s just say after tallying the costs for the car, the gold theme becomes very appropriate.

When things go wrong with cars during the modification process, its very easy to cuss out, lose motivation and call it quits. This is even more amplified when the car you’re modifying already cost over $100k and you’ve just lost an additional $40k on a blown engine and diff so to that, I think there’s no denying Tony’s perseverance to carry on. Despite the setbacks, sleepless nights during his build failure and thousands of lost dollars, Tony says when he’s ripping it down Queensland Raceway he instantly forgets these past experiences and enjoys the moment he’s in. Tony would like to call out his thanks to Aaron and team from Precision Racing, Lucas from Vouge Industries, Cameron and Joshua Hill for the body work and most importantly his wife who’s been patient and supportive throughout the entire process, no matter how stupid it may have seemed at the time.

SUGGESTED POSTS

Years In The Making: Gus’s Heavily Modified R32 GTR

There are very few cars that have expanded the minds of tuners to…

947hp Built RB26/30 VL: Aussie Cult Classic With A Twist

Turbochargers are now a staple engine component in the majority of…

A Skyline GTST 4 Door That’s Worth Going Into D3BT For

Had the Skyline name not become so tightly attached to the more…

Anthony From Dahtone Racing Knows How To GTR

GTR. Three letters that represent a machine that nearly every car…

An RX-7 On Blitz 03 Wheels: A Match Made In Heaven

Luckily for Eric, he managed to secure a set of Blitz 03 wheels. He…

A Slammed & Swapped RB25 S14 That’s Build To Be Driven

The life of a tuner can be a difficult one. You are constantly…

Alex’s TE4SER Kouki S14 Ticks All The Boxes

It’s often said that you never fully appreciate something you have…

Keenan’s Spoon Inspired EG Civic: Built for the street

The Honda scene has had a welcome resurgence in the past few years.…